The global chemicals sector comprises a complex mix of industries and products, contributing to a significant collective carbon footprint

CO2 emissions must decouple from production by 2030 to get on track with the Net Zero Emissions by 2050 Scenario.

International Energy Agency

Deliver decarbonised chemicals

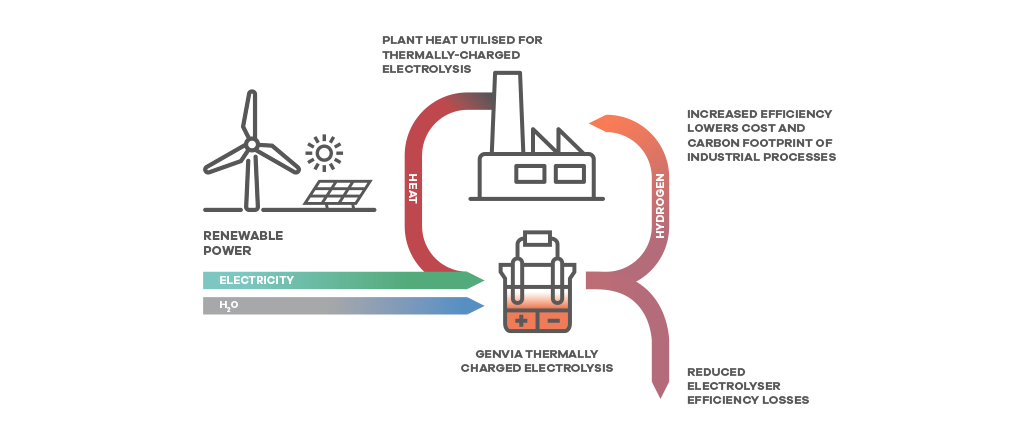

Powered by low-carbon electricity sources, Genvia provides chemical plants with new opportunities to produce greener products and contribute to a cleaner value chain. Our technologies have application across a broad variety of large-scale industrial processes, from ammonia production to plastics.

Reduce thermal losses, lower emissions

Thermally-charged electrolysis has been engineered to consume less electrical energy than competing systems while producing an equivalent volume of hydrogen. Coupling exothermic reactions to steam generation improves electrolysis efficiency.

More hydrogen, fewer losses

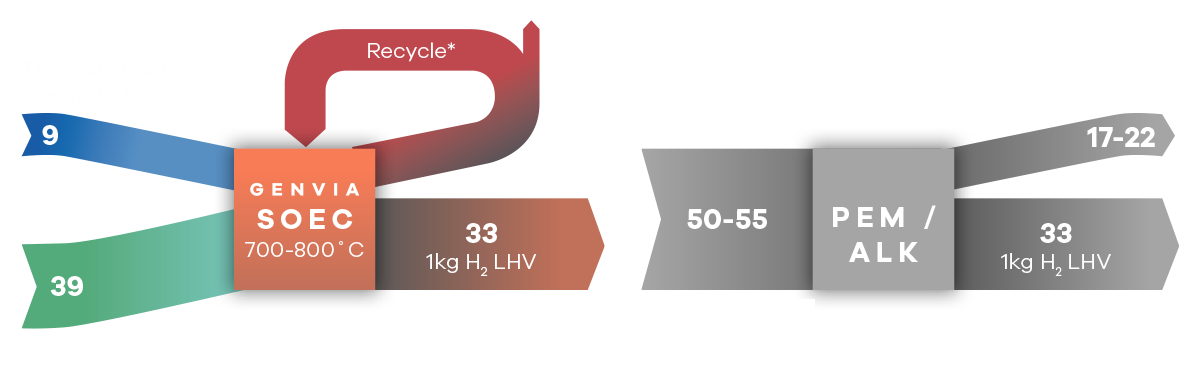

Genvia’s high efficiency solid oxide technology delivers more energy-efficient electrolysis performance when compared to existing PEM and alkaline-based systems.

*Percentage recycle improving with development

Numbers in kWhr/kg H2

However hydrogen fits into your decarbonisation strategy, speak to Genvia about ways to produce higher volumes of H2 in-situ at a lower electricity input.