Deliver disruption-free transition: Hydrogen

As today’s industrial plants produce the vital ingredients and catalysts that drive a range of sectors, this transition to higher efficiency hydrogen production must happen in way that protects the continuity of ongoing operations.

Rather than immediate change or wholesale replacement, avoiding disruption demands an integrated approach that enables complementary solutions to work alongside systems currently in use.

And rather than scrapping established systems, it calls for a practical plan that protects plant investment by building the transition into the operational lifecycle of existing equipment.

Develop production without interruption

By considering capex and opex – as well as exploring opportunities to accommodate your existing equipment – our goal is to provide every plant with the most predictable, cost-effective carbon reduction programme.

Production uptime is protected by digital monitoring; providing access to the performance data required for prognostic health management and preventative maintenance. At the same time design is optimized as part of our commitment to a continuous improvement process.

And in contrast to short-term sales relationships, your Genvia team offers the longer-term engagement that supports the successful transformation of industrial processes.

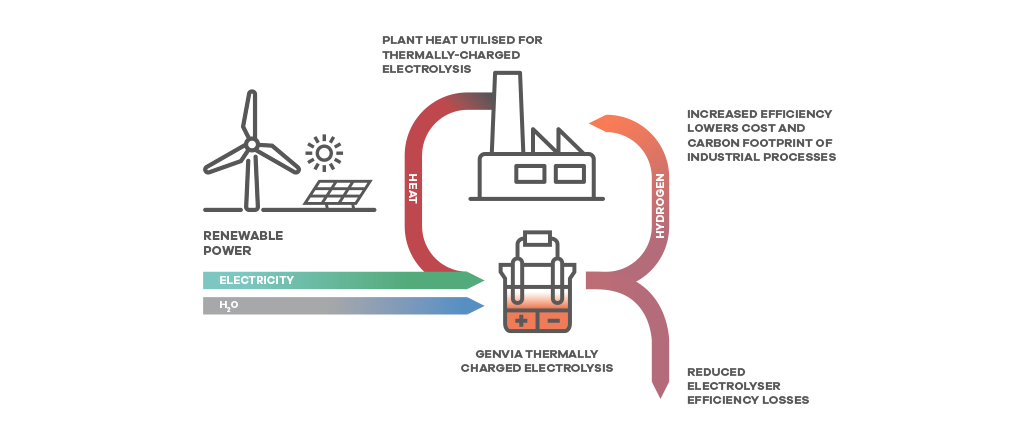

Genvia is engineering industrial-scale solutions for the reduction of CO2 emissions – solid oxide electrolysis systems proven to produce hydrogen with greater reliability and higher energy efficiency than both alkaline and PEM-based methods.